How Fast to Turn a Propeller.

I have a model tug hull with a 60 mm propeller. The question is, how fast should it turn? The starting points for the answer are the propeller pitch, that’s the distance through the water that the propeller would move in 1 turn, all other things being perfect, and the maximum speed of the boat.

I don’t know the actual propeller pitch, but a good guess is about the same as the propeller diameter. That’s common for propellers for non-planing hulls. So 60 mm. is about 2.36 inches. I’ll start with that.

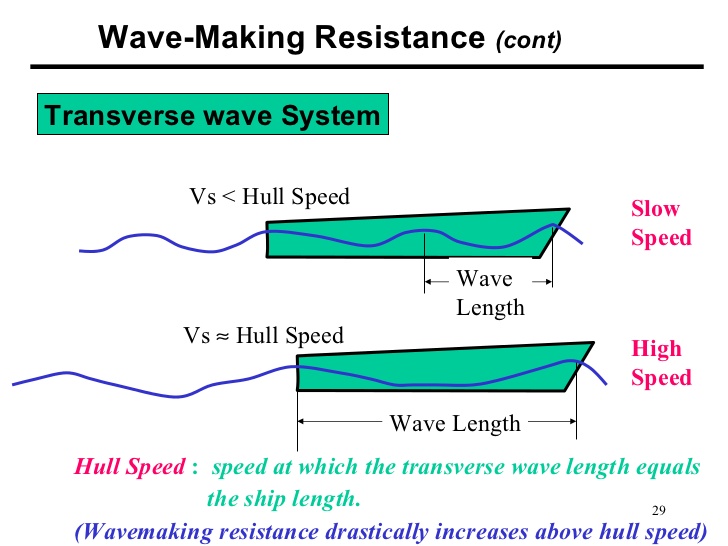

A hull that doesn’t plane has a maximum speed at which the power needed to go faster gets huge. At this speed the boat creates waves that are about the same length as the boat hull, and to go faster, the boat has to, in effect, climb up and over its own bow wave.

There’s a mathematical formula for this speed. The maximum hull speed in knots is 1.34 times the square root of the waterline length of the hull in feet. My tug hull is 37 inches long overall and the waterline length is going to be very close to 36 inches, 3 feet. So the maximum speed for this hull is 1.34 times the square root of 3. That comes to 2.32 knots. ( The full size tug, 72 feet on the waterline, would be making 11 knots).

One knot is, believe it or not, 1,215 inches per minute. So my tug, at maximum speed, will be travelling at 2.32 times that, or 2,815 inches per minute. The propeller pitch is 2.36 inches, so, under perfect conditions, the prop would be turning at 2,815 divided by 2.36. That’s 1192 revs per minute.

In real life, of course, the hull doesn’t move the full distance of the propeller pitch. The difference is called propeller slip. In full size boats, the slip can be as much as 45% for one of those little two-blade folding props that supply auxiliary power to a sailboat, or better than 90% for a big, slow, 4-blade prop on an unloaded tug. For my model, with the three blade prop, I’m going to guess at 80%, so I’ll need more revs. Just about 1500 of them.

Right, I ordered a 775 motor, 3000 rpm at 12 volts, with a 3:1 toothed belt reduction gear. The motor performance curves say it’ll be at its maximum efficiency at 85% of the no-load speed. I know for sure that the 775 will have huge spare horsepower and torque available for this size hull, so I’m going to assume 90% of no load speed at the motor shaft, or 2700 rpm. So the reduction gear should be 1.8 to 1 rather than 3 to 1. That’s quite a nice answer. The motor pulley I have coming is 20 teeth and the shaft pulley 60 teeth. If I order a 36 tooth shaft pulley, the gearing will be right and I’m going to save quite a bit of space for mounting the motor.

It’s not the only answer though. The motor is rated for higher voltages, and the no-load speed is proportional to the battery voltage. That will, of course, add to the horsepower even more. Or I am still very tempted by up-sizing the prop. I’m sure I could squeeze in a 75 mm four blade prop, raising the pitch and reducing the slip. That’ll look sooo cool!

Anyway, I can order a couple more shaft pulleys, a 36 tooth and a 42, and the whole build is in the ball park, power and speed wise. So, this afternoon, find the lead pucks and fill the bath, to measure the displacement of this hull, and then I can look at the weight of batteries I can afford to use.

On we go.